O-Ring S51

DESCRIPTION

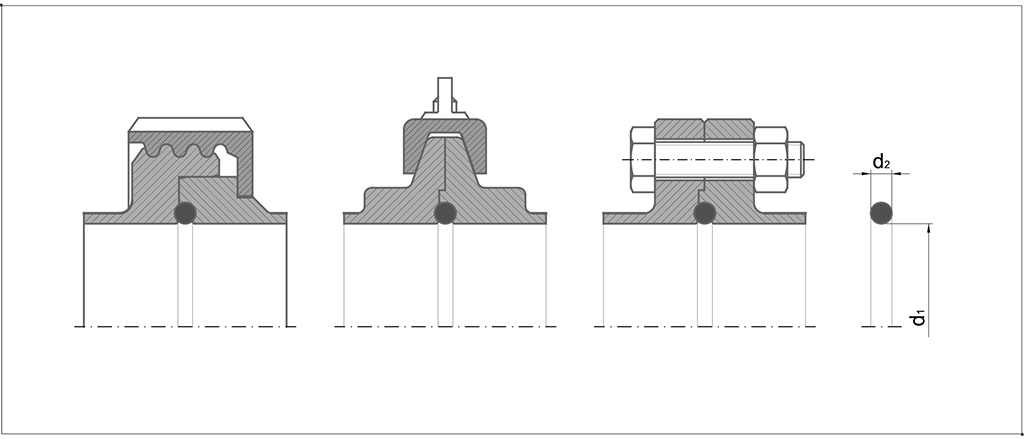

Process O-rings are used to connect two pipes and are standardized according to DIN 11864 -1, -2, -3 for tubes acc. to DIN 11866 serie A, B, C.

The advantages of these rings are reliable operation in steam, water and aqueous solutions of chemicals. Also, these rings reduce maintenance and keep equipment running longer, faster and under higher pressures.

Standardised sealing element and fast and easy assembly regardless od the direction of installation are also great advantages.

APPLICATION

Process industry and fluid handling generaly. Particularly in food industries especially pharmaceutical industries

| Standard material | ||||||

|---|---|---|---|---|---|---|

| Material code | Material base | Color | Croslinking | Hardness Shore A | Temperature range in air oC | Area of application |

| E5540 | EPDM | black | peroxidic | 75±5 | -40 to +150 | Hot water and steam up to 180 oC, Acids (hydrochloric, nitric and phosphoric acid), Alcaline solutions (sodium hydroxide solution and potassium hydroxide solution). Polar organic solvent. CIP/SIP media. |

| F9970 | FPM | black | peroxidic | 75±5 | -15 to +200 | Excelent resistance in hot water, steam and alcohols. Very well suited at high temperatures, for use in animal and vegetable fats and oils, aliphatic and aromatics hydrocarbons, also in essential oils. Resistant to CIP/SIP media for continious operation plants in the food and pharmaceutical industries for short cleaning cycles |

The seals are installed without a particular orientation because the flanges are designed symmetrically. When the seal is properly seated and compressed on installation there is no the danger that leakage can occur

Nominal Size DN | DIN 11866 tube Serie | Ø d1 (mm) | Tol ± | Ø d2 (mm) | Tol ± | Material | Order code | ||

|---|---|---|---|---|---|---|---|---|---|

10 |

A |

12 |

0.21 |

3.5 |

0.1 |

F9970 |

S51-101005 |

||

10 |

A |

12 |

0.21 |

3.5 |

0.1 |

EPDM |

S51-101040 |

||

13.5 |

B |

12 |

0.21 |

3.5 |

0.1 |

F9970 |

S51-101005 |

||

13.5 |

B |

12 |

0.21 |

3.5 |

0.1 |

EPDM |

S51-101040 |

||

15 |

A |

18 |

0.25 |

3.5 |

0.1 |

F9970 |

S51-101007 |

||

15 |

A |

18 |

0.25 |

3.5 |

0.1 |

EPDM |

S51-101042 |

||

17.2 |

B |

16 |

0.24 |

3.5 |

0.1 |

F9970 |

S51-101006 |

||

17.2 |

B |

16 |

0.24 |

3.5 |

0.1 |

EPDM |

S51-101041 |

||

20 |

A |

22 |

0.28 |

3.5 |

0.1 |

F9970 |

S51-101009 |

||

20 |

A |

22 |

0.28 |

3.5 |

0.1 |

EPDM |

S51-101044 |

||

21.3 |

B |

20 |

0.26 |

3.5 |

0.1 |

F9970 |

S51-101008 |

||

21.3 |

B |

20 |

0.26 |

3.5 |

0.1 |

EPDM |

S51-101043 |

||

25 |

A |

28 |

0.32 |

3.5 |

0.1 |

F9970 |

S51-101012 |

||

25 |

A |

28 |

0.32 |

3.5 |

0.1 |

EPDM |

S51-101047 |

||

26.9 |

B |

26 |

0.31 |

3.5 |

0.1 |

F9970 |

S51-101011 |

||

26.9 |

B |

26 |

0.31 |

3.5 |

0.1 |

EPDM |

S51-101046 |

||

32 |

A |

34 |

0.37 |

5 |

0.13 |

F9970 |

S51-101014 |

||

32 |

A |

34 |

0.37 |

5 |

0.13 |

EPDM |

S51-101049 |

||

33.7 |

B |

32 |

0.35 |

5 |

0.13 |

F9970 |

S51-101013 |

||

33.7 |

B |

32 |

0.35 |

5 |

0.13 |

EPDM |

S51-101048 |

||

40 |

A |

40 |

0.41 |

5 |

0.13 |

F9970 |

S51-101016 |

||

40 |

A |

40 |

0.41 |

5 |

0.13 |

EPDM |

S51-101051 |

||

42.7 |

B |

40.5 |

0.41 |

5 |

0.13 |

F9970 |

S51-101017 |

||

42.7 |

B |

40.5 |

0.41 |

5 |

0.13 |

EPDM |

S51-101052 |

||

48.3 |

B |

46.5 |

0.46 |

5 |

0.13 |

F9970 |

S51-101018 |

||

48.3 |

B |

46.5 |

0.46 |

5 |

0.13 |

EPDM |

S51-101053 |

||

50 |

A |

52 |

0.49 |

5 |

0.13 |

F9970 |

S51-101020 |

||

50 |

A |

52 |

0.49 |

5 |

0.13 |

EPDM |

S51-101055 |

||

60.3 |

B |

58.5 |

0.54 |

5 |

0.13 |

F9970 |

S51-101021 |

||

60.3 |

B |

58.5 |

0.54 |

5 |

0.13 |

EPDM |

S51-101056 |

||

65 |

A |

68 |

0.61 |

5 |

0.13 |

F9970 |

S51-101023 |

||

65 |

A |

68 |

0.61 |

5 |

0.13 |

EPDM |

S51-101058 |

||

76.1 |

B |

73.5 |

0.64 |

5 |

0.13 |

F9970 |

S51-101024 |

||

76.1 |

B |

73.5 |

0.64 |

5 |

0.13 |

EPDM |

S51-101059 |

||

80 |

A |

83 |

0.71 |

5 |

0.13 |

F9970 |

S51-101026 |

||

80 |

A |

83 |

0.71 |

5 |

0.13 |

EPDM |

S51-101061 |

||

88.9 |

B |

85.5 |

0.73 |

5 |

0.13 |

F9970 |

S51-101027 |

||

88.9 |

B |

85.5 |

0.73 |

5 |

0.13 |

EPDM |

S51-101062 |

||

100 |

A |

102 |

0.84 |

5 |

0.13 |

F9970 |

S51-101029 |

||

100 |

A |

102 |

0.84 |

5 |

0.13 |

EPDM |

S51-101064 |

||

114.3 |

B |

111 |

0.90 |

5 |

0.13 |

F9970 |

S51-101030 |

||

114.3 |

B |

111 |

0.90 |

5 |

0.13 |

EPDM |

S51-101065 |

||

125 |

A |

127 |

1.01 |

5 |

0.13 |

F9970 |

S51-101031 |

||

125 |

A |

127 |

1.01 |

5 |

0.13 |

EPDM |

S51-101066 |

||

150 |

A |

152 |

1.17 |

5 |

0.13 |

F9970 |

S51-101032 |

||

150 |

A |

152 |

1.17 |

5 |

0.13 |

EPDM |

S51-101067 |

||

½“ |

C |

12 |

0.21 |

3.5 |

0.1 |

F9970 |

S51-101005 |

||

½“ |

C |

12 |

0.21 |

3.5 |

0.1 |

EPDM |

S51-101040 |

||

¾“ |

C |

18 |

0.25 |

3.5 |

0.1 |

F9970 |

S51-101007 |

||

¾“ |

C |

18 |

0.25 |

3.5 |

0.1 |

EPDM |

S51-101042 |