V-Seal Set R04

DESCRIPTION

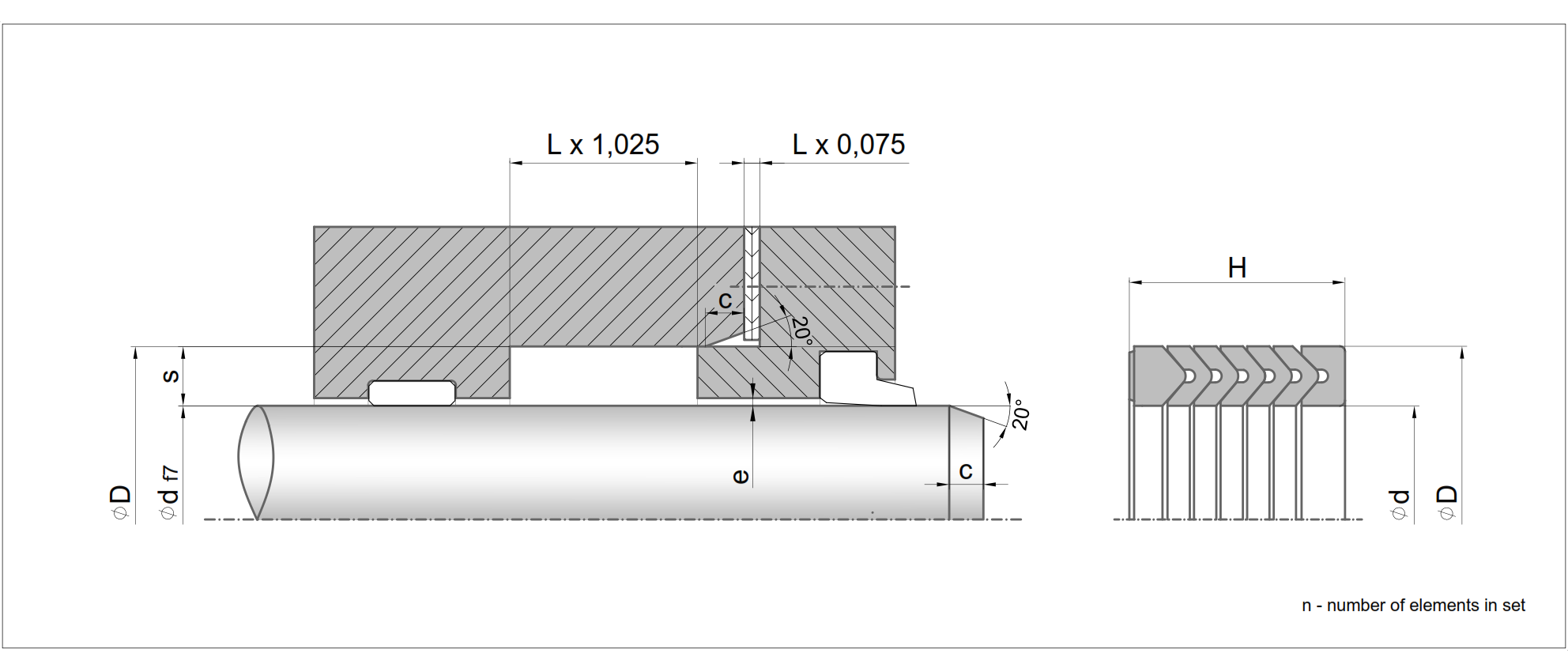

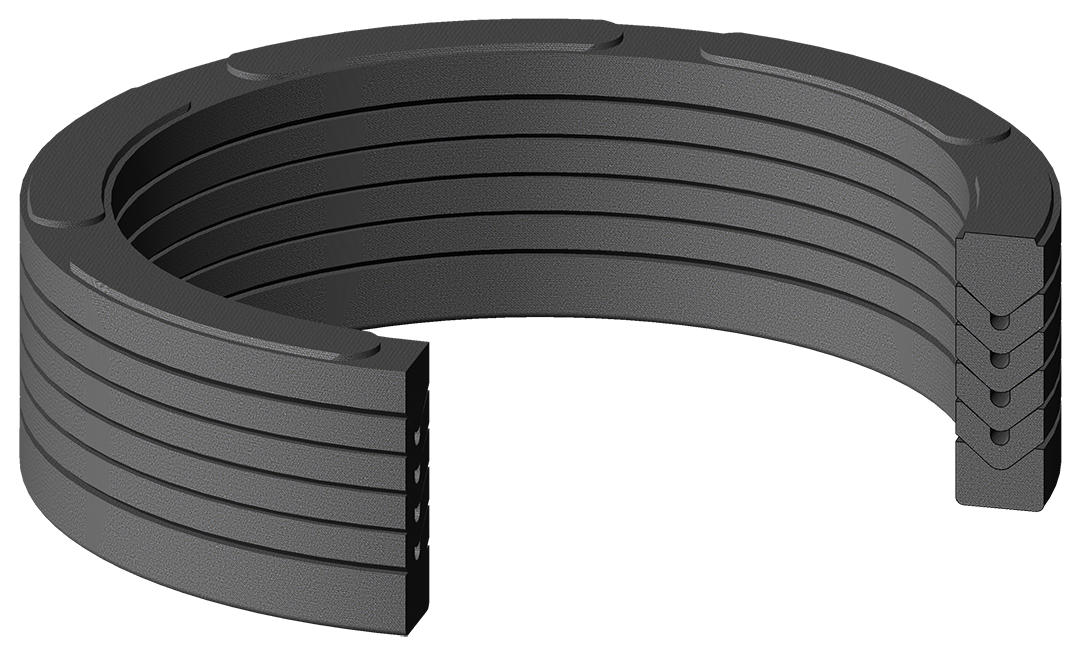

Chevron seal set R04 for sealing piston rods. Set includes five (n=5), or six (n=6), or seven (n=7) pieces: Pressure ring, Support ring, and V-rings in quantity till number (n)

Read More

APPLICATION

Mining equipment

Injection molding machines

Presses

Escavator cylinders

Steel mill cylinders

Water hydraulics

MATERIAL

| Material | ||

|---|---|---|

| Material Set Code, standard | SN102 | SF106 |

| Rubber | NBR | FKM |

| Fabric reinforcement | Cotton | Cotton |

For very low temperature applications up to -60 C, or excellent oils-rubber compatybility in special applications a few materials are recommended and available on request.

| Pressure, Speed | |

|---|---|

| Working pressure, P | 40 MPa |

| Running speed, v | 0,5 m/s |

| Medium, Working Temperature | ||

|---|---|---|

| Material Set Code | SN102 | SF106 |

| Hydraulic oils: HL, HLP | -30.. +100 ˚C | -15.. +150 ˚C |

| HFA, HFB fluids | +5..+60 °C | +5..+60 °C |

| HFC fluids | -30..+60˚C | -15.. +60 ˚C |

| HFD fluids | – | -15.. +150 ˚C |

| Water | +5..+100 °C | +5..+ 80 ˚C |

| Mineral greases | -30..+100°C | -15.. +150 ˚C |

| Tolerances | ||

|---|---|---|

| Ød | Clearance fit, emax | ØD |

| > 120 to 500 | H8/f7 | H11 |

| > 500 to 630 | H8/f7 | H10 |

| > 630 to 800 | H8/f7 | H10 |

| > 800 to 1000 | H8/f7 | H10 |

Filters

Sort results

Reset

Apply

Ød | ØD | L | S | C | n | Material | Order code | Sing in | |

|---|---|---|---|---|---|---|---|---|---|

150 |

180 |

45 |

15 |

7.50 |

5 |

SN102 |

R04-888001 |

||

150 |

180 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888002 |

||

160 |

185 |

40 |

12.5 |

7.50 |

5 |

SN102 |

R04-888003 |

||

160 |

190 |

45 |

15 |

7.50 |

5 |

SN102 |

R04-888004 |

||

160 |

190 |

50 |

15 |

7.50 |

5 |

SN102 |

R04-888005 |

||

160 |

190 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888006 |

||

180 |

205 |

40 |

12.5 |

7.50 |

5 |

SN102 |

R04-888007 |

||

180 |

210 |

45 |

15 |

7.50 |

5 |

SN102 |

R04-888008 |

||

180 |

210 |

50 |

15 |

7.50 |

5 |

SN102 |

R04-888009 |

||

180 |

210 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888010 |

||

200 |

225 |

40 |

12.5 |

7.50 |

5 |

SN102 |

R04-888011 |

||

200 |

230 |

45 |

15 |

7.50 |

5 |

SN102 |

R04-888012 |

||

200 |

230 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888013 |

||

200 |

230 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888014 |

||

200 |

230 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888015 |

||

205 |

235 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888016 |

||

210 |

240 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888017 |

||

210 |

240 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888018 |

||

210 |

240 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888019 |

||

215 |

245 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888020 |

||

215 |

245 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888021 |

||

215 |

245 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888022 |

||

220 |

250 |

50 |

15 |

7.50 |

6 |

SN102 |

R04-888023 |

||

220 |

250 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888024 |

||

220 |

250 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888025 |

||

220 |

250 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888026 |

||

225 |

255 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888027 |

||

225 |

255 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888028 |

||

225 |

255 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888029 |

||

230 |

260 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888030 |

||

230 |

260 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888031 |

||

230 |

260 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888032 |

||

235 |

265 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888033 |

||

235 |

265 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888034 |

||

235 |

265 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888035 |

||

240 |

270 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888036 |

||

240 |

270 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888037 |

||

240 |

270 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888038 |

||

245 |

275 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888039 |

||

250 |

280 |

50 |

15 |

7.50 |

6 |

SN102 |

R04-888040 |

||

250 |

280 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888041 |

||

250 |

280 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888042 |

||

250 |

280 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888043 |

||

255 |

285 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888044 |

||

260 |

290 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888045 |

||

260 |

290 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888046 |

||

260 |

290 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888047 |

||

265 |

295 |

60 |

15 |

7.50 |

7 |

SN102 |

R04-888048 |

||

270 |

300 |

50.50 |

15 |

7.50 |

5 |

SN102 |

R04-888049 |

||

270 |

300 |

52.50 |

15 |

7.50 |

6 |

SN102 |

R04-888050 |