Piston Seal Set P23

DESCRIPTION

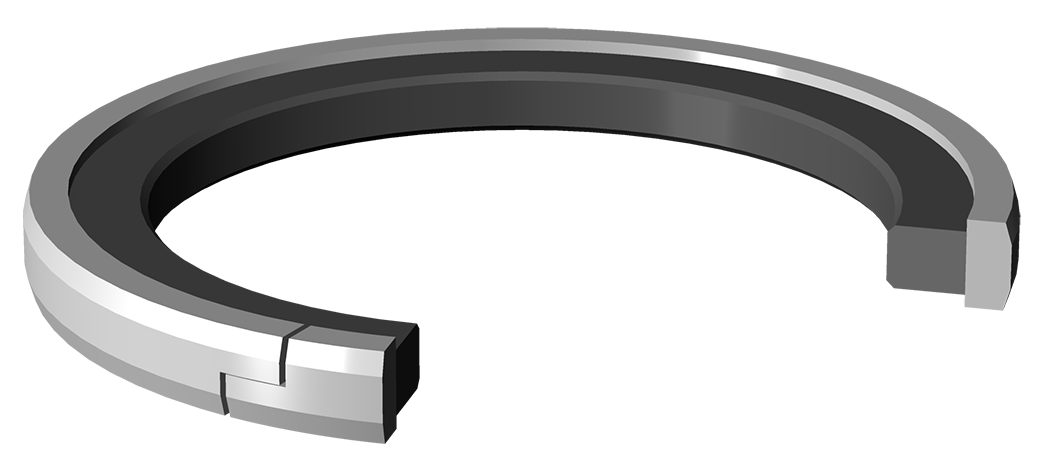

Piston Seal Set P23 is consisting of polyamide slide ring with stepped cut and an rubber ring as energising element.

Seal set P23 is duoble acting seal for hevy duty application and housing according to ISO 7425-1. The stepped cut facilitates easy instalation in small or closed housing while rubber ring square section offer protection against twisting.

Features of this seal are very high static and dynamic sealing effect, very high resistance to abrasion, resistance against pressure, extrusion, and low friction without the appearance of stick-slip.

APPLICATION

Earth moving equipment

Mobile hydraulics

Truck cranes

Construction machinery

Agricultural equipment

| Standard material | |

|---|---|

| Material Set Code | SN251 |

| O-ring NBR 70 ShA, Code | N4913 |

| PA modified, Code | P6411 |

In special applications in terms of temperature or medium-rubber compatibility, several materials are recommended and available on request.

| Pressure, Speed | |

|---|---|

| Working pressure, p dynamic | 60 Mpa |

| Working pressure, p, static | 80 Mpa |

| Running speed, v in m/s | Up to 1,0 m/s |

| Media, Operating temperature | |

|---|---|

| Material Set Code | SN251 |

| Hydraulic oils: HL, HLP | -30.. +100 ˚C |

| HFA, HFB fluids | +5..+ 50 °C |

| HFC fluids | -30..+50 °C |

| HFD fluids | – |

| Water | – |

| Mineral greases | -30.. +100 ˚C |

| Max. permissible gap dimension, emax | |||||

|---|---|---|---|---|---|

| Profile size | Max operating pressure | ||||

| L | S | ≤32 MPa | 40 Mpa | 60 Mpa | 80 Mpa |

| 4,2 | 5,50 | 0,55 | 0,50 | 0,30 | 0,20 |

| 6,3 | 7,55 | 0,75 | 0,70 | 0,50 | 0,25 |

| 8,1 | 10,50 | 1,00 | 0,90 | 0,60 | 0,35 |

| Surface quality* | ||

|---|---|---|

| Surface roughness | Ra | Rmax |

| Sliding surfaces | 0.05 .. 0,3μm | ≤ 2,5 μm |

| Groove base | ≤ 1,6 μm | ≤ 6,3 μm |

| Groove flanks | ≤ 3,0 μm | ≤ 15 μm |

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

ØD | Ød | H | L | S | C | Material | Order code | Quantity | Sing in |

|---|---|---|---|---|---|---|---|---|---|

32 |

21 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126104 |

||

40 |

29 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126105 |

||

45 |

34 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126106 |

||

50 |

34.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126107 |

||

50 |

39 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126108 |

||

60 |

49 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126109 |

||

63 |

47.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126110 |

||

63 |

52 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126111 |

||

70 |

54.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126112 |

||

70 |

59 |

4 |

4.2 |

5.5 |

5 |

SN251 |

P23-126113 |

||

75 |

59.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126114 |

||

80 |

59 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126115 |

||

80 |

64.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126116 |

||

85 |

64 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126117 |

||

90 |

69 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126118 |

||

90 |

74.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126119 |

||

95 |

74 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126120 |

||

100 |

79 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126121 |

||

100 |

84.5 |

6.1 |

6.3 |

7.75 |

5 |

SN251 |

P23-126122 |

||

105 |

84 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126123 |

||

110 |

89 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126124 |

||

115 |

94 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126125 |

||

120 |

99 |

7.8 |

8.1 |

10.5 |

5 |

SN251 |

P23-126126 |

||

125 |

104 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126127 |

||

130 |

109 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126128 |

||

140 |

119 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126129 |

||

150 |

129 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126130 |

||

160 |

139 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126131 |

||

170 |

149 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126132 |

||

180 |

159 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126133 |

||

190 |

169 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126134 |

||

200 |

179 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126135 |

||

220 |

199 |

7.8 |

8.1 |

10.5 |

6.50 |

SN251 |

P23-126136 |