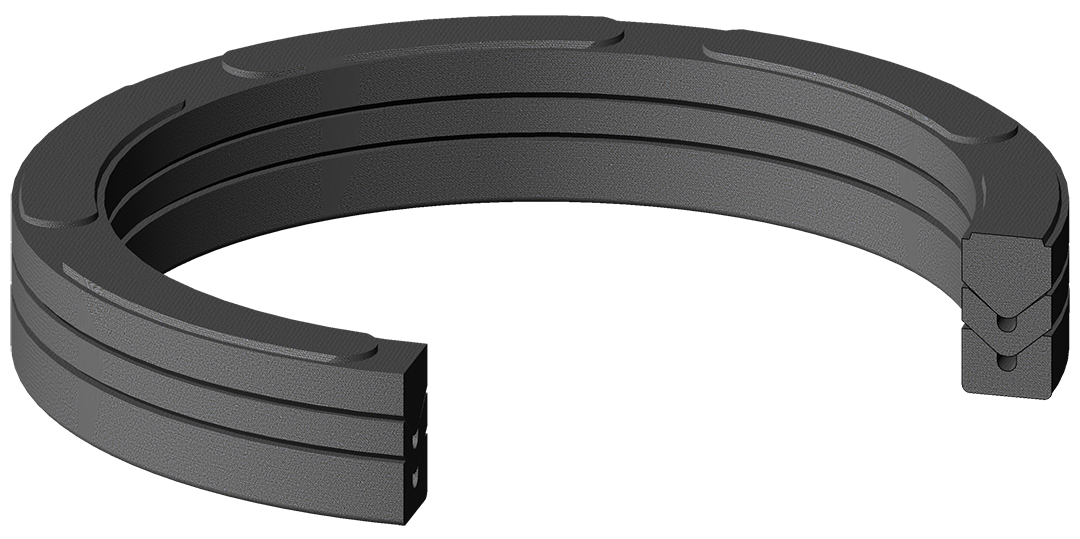

Piston seal P05

DESCRIPTION

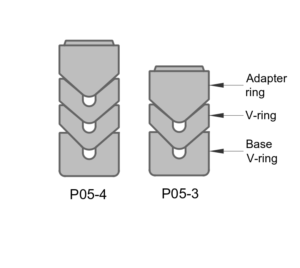

Piston seal P05 is a seal made of rubber-reinforced fabric and is used to seal hydraulic cylinders. It consists of several parts: one base ring, two or three V-shaped seals and one ring in the function of an adapter.

The base V-ring is the basic element in the package and has the role of carrying the other elements. It is subjected to particularly heavy loads, so it is made of fabric reinforced with hard rubber with good resistance to wear and deformation.

V-rings transmit the received force to the surfaces of the groove and the connecting rod, realizing the sealing function.

The ring adapter distributes the axial preload force and operating pressure force to the V-rings in the package

The P05 package is reliable and has excellent behavior even under extremely heavy load operating conditions. It has exceptional wear resistance and a long service life.

APPLICATION

Mining equipment

Presses

Scrap cutters

Steel mill cylinders

Water hydraulics

Special cylinders

| Standard material | ||

|---|---|---|

| Material Set Code, standard | SN102 | SF106 |

| Rubber | NBR | FKM |

| Fabric reinforcement | Cotton | Cotton |

Alternate materials:

For very low temperature applications up to -60 C, or excellent oils-rubber compatybility in special applications a few materials are recommended and available on request.

| Pressure, Speed | |

|---|---|

| Working pressure, P | 40 MPa |

| Running speed, v | 0,5 m/s |

| Medium, Working Temperature | ||

|---|---|---|

| Material Set Code | SN102 | SF106 |

| Hydraulic oils: HL, HLP | -30.. +100 ˚C | -15.. +150 ˚C |

| HFA, HFB fluids | +5..+60 °C | +5..+60 °C |

| HFC fluids | -30..+60˚C | – |

| HFD fluids | – | -15.. +150 ˚C |

| Water | +5..+100 °C | +5..+ 80 ˚C |

| Mineral greases | -30..+100°C | -15.. +150 ˚C |

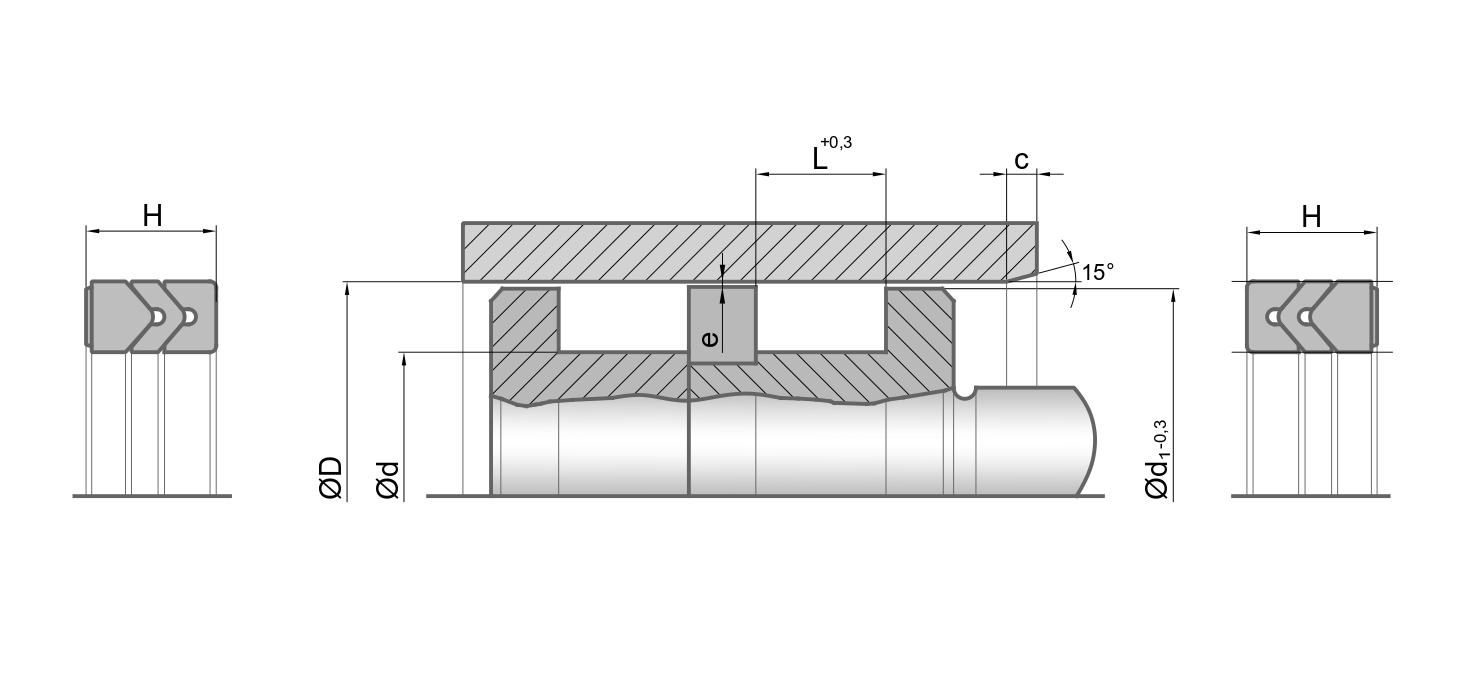

| Tolerances | ||

|---|---|---|

| Ød | Clearance fit, e | ØD |

| …80 | H9/f8 | h11 |

| > 80 … 120 | H8/f8 | h11 |

| > 120 … 500 | H8/f7 | h11 |

| > 500 … 630 | H8/f7 | h11 |

| > 630 … 800 | H8/f7 | h11 |

| Surface finish* | ||

|---|---|---|

| Surface roughness | Ra | Rmax |

| Sliding surfaces | 0,05 to 0,3μm | ≤ 2,5 μm |

| Groove base | ≤ 1,6 μm | ≤ 6,3 μm |

| Groove flanks | ≤ 3,0 μm | ≤ 15 μm |

| Chamfer | ≤ 4,0 μm | ≤ 16 μm |

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

| Width profile, S, mm | Lead-in chmfers, C, mm |

|---|---|

| > 7.5 .. ≤ 10 | 5 |

| > 10 .. ≤ 15 | 7.5 |

| > 15 .. ≤ 20 | 10 |