STATIC SEAL S34

DESCRIPTION

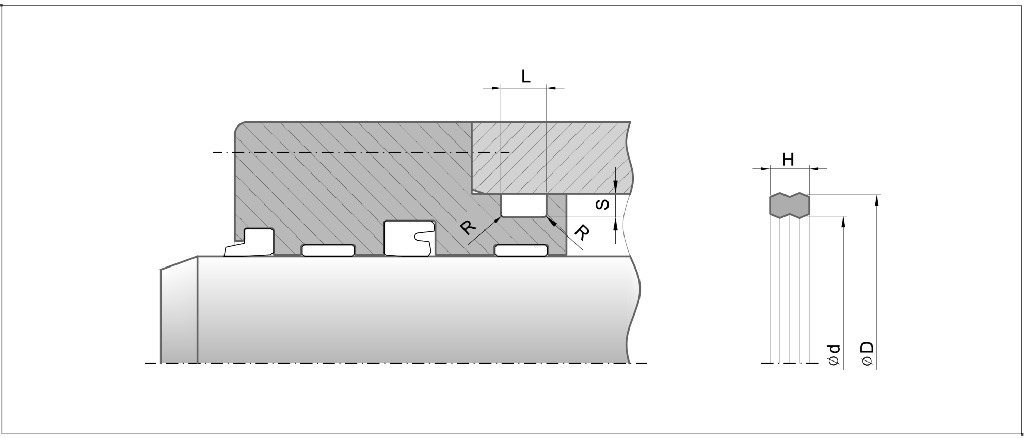

Static Seal S34 used as an alternative to conventially used O-ring/back-up ring combinations for radial static seling applicationas at high pressures.

Symetrical sealing geometry and low compression set and extrusion resistance material secure excellent sealing performance even in pulsating pressuress conditions.

Read More

APPLICATION

Standard hydraulic cylinders

Industrial vehicle

Injection moulding machines

Presess

Stabilizer cilinders

Agriculture equipment

Construction machinery

Machime tools.

| Standard material | |

|---|---|

| Material code | U5017 |

| Material base | Polyurethane |

| Hardness, Shore A | 94 |

| Color | Dark blue |

| Pressure, Speed | |||

|---|---|---|---|

| Working pressure | Max 50 Mpa | ||

| Medium, Working Temperature | |||

|---|---|---|---|

| Hydraulic oils: HL, HLP | -30 … +110 °C | ||

| HFA, HFB fluids | +5 … +60 oC | ||

| HFC fluids | -30 … +40 °C | ||

| Water | +5 … +50 oC | ||

| Mineral greases | -30 … +110 °C | ||

| Max. permissible gap dimension, emax, mm | |||

|---|---|---|---|

| Sealing gap for U5017 | Up to 0.2 | ||

| Preferred sealing gap, generally | H8/g6 | ||

| Surface quality* | |||

|---|---|---|---|

| Ra | Rt | ||

| Sealing surfaces | ≤ 1,6μm | ≤ 10 μm | |

| Groove base | ≤ 3,2μm | ≤ 16 μm | |

| Groove flanks | ≤ 3,2μm | ≤ 16 μm | |

INSTALLATION

The seals do not be pulled over a sharp edges during installation.

Normally these seals may be snapped into closed groves. Where access is restricted special tools may be required

Filters

Sort results

Reset

Apply

ØD H8

| Ød h9 | L +0.2 | H -0.2 | S | R -0.2 | Material | Order code | ||

|---|---|---|---|---|---|---|---|---|---|

10.0 |

7.4 |

2.4 |

2.2 |

1.3 |

0.3 |

U5017 |

S34-044005 |

||

10.0 |

7.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044006 |

||

11.0 |

8.6 |

2.6 |

2.2 |

1.2 |

0.3 |

U5017 |

S34-044007 |

||

12.0 |

9.4 |

2.4 |

2.2 |

1.3 |

0.3 |

U5017 |

S34-044008 |

||

12.0 |

9.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044009 |

||

12.0 |

9.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044010 |

||

13.0 |

10.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044011 |

||

14.0 |

11.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044012 |

||

14.0 |

11.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044013 |

||

15.0 |

12.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044014 |

||

15.0 |

12.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044015 |

||

15.0 |

12.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044016 |

||

15.8 |

13.2 |

3.6 |

3 |

1.3 |

0.3 |

U5017 |

S34-044092 |

||

16.0 |

13.4 |

2.4 |

2.2 |

1.3 |

0.3 |

U5017 |

S34-044017 |

||

16.0 |

13.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044018 |

||

16.0 |

13.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044019 |

||

17.0 |

14.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044020 |

||

17.0 |

14.6 |

2.6 |

2.2 |

1.2 |

0.3 |

U5017 |

S34-044021 |

||

17.0 |

14.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044022 |

||

17.4 |

14.8 |

3.6 |

3 |

1.3 |

0.3 |

U5017 |

S34-044093 |

||

18.0 |

15.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044023 |

||

18.0 |

15.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044024 |

||

18.0 |

15.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044025 |

||

19.0 |

16.2 |

2.6 |

2.2 |

1.4 |

0.3 |

U5017 |

S34-044026 |

||

19.0 |

16.6 |

2.6 |

2.2 |

1.2 |

0.3 |

U5017 |

S34-044027 |

||

19.0 |

16.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044028 |

||

19.0 |

16.4 |

3.6 |

3 |

1.3 |

0.3 |

U5017 |

S34-044094 |

||

20.0 |

17.4 |

2.4 |

2.2 |

1.3 |

0.3 |

U5017 |

S34-044029 |

||

20.0 |

17.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044030 |

||

20.0 |

17.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044031 |

||

21.0 |

18.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044032 |

||

22.0 |

19.4 |

2.4 |

2.2 |

1.3 |

0.3 |

U5017 |

S34-044033 |

||

22.0 |

19.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044034 |

||

22.0 |

19.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044035 |

||

23.0 |

20.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044036 |

||

24.0 |

21.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044037 |

||

24.0 |

21.4 |

5.4 |

4.4 |

1.3 |

0.4 |

U5017 |

S34-044095 |

||

24.0 |

21.6 |

3.6 |

3 |

1.2 |

0.3 |

U5017 |

S34-044038 |

||

25.0 |

22.4 |

3.8 |

3.2 |

1.3 |

0.3 |

U5017 |

S34-044039 |

||

25.4 |

22.8 |

5.4 |

4.4 |

1.3 |

0.4 |

U5017 |

S34-044096 |

||

26.0 |

22.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044040 |

||

27.0 |

24.4 |

5.4 |

4.4 |

1.3 |

0.4 |

U5017 |

S34-044097 |

||

28.0 |

24.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044041 |

||

28.6 |

26.0 |

5.4 |

4.4 |

1.3 |

0.4 |

U5017 |

S34-044098 |

||

30.0 |

25.4 |

5.4 |

4.4 |

2.3 |

0.4 |

U5017 |

S34-044042 |

||

30.0 |

26.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044132 |

||

32.0 |

27.4 |

5.4 |

4.4 |

2.3 |

0.4 |

U5017 |

S34-044044 |

||

32.0 |

28.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044045 |

||

34.0 |

30.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044046 |

||

35.0 |

31.0 |

5 |

4 |

2 |

0.3 |

U5017 |

S34-044047 |