V-Seal Set R02

DESCRIPTION

V-seal set R02 is packing set for sealing piston rods. Set includes seven pieces.

Packing R02 is reliable even under extreme operating conditions and has excellent behavior in harsh conditions. It has exceptional wear resistance and long service life.

- Pressure ring is a base ring that hold the V-rings in set. It is manufactured in fabric impregnated with hard rubber

- V-Rings are manufactured in fabric impregnated with rubber

- V-rings is made in rubber for higher sealing efficiency

- Support ring are made in rubber reinforced fabric or in plastics (POM).

The R02 pack achieves sealing by doing so the suport ring distribute the axial compression force of the fluid to the V-rings in the pack and bring them into positive contact with the piston rod surface, groove surfaces, and pressure ring.

APPLICATION

Mining equipment, Injection molding machines, Presses, Escavator cylinders, Steel mill cylinders, Water hydraulics, Scrap cutters, Marine hydraulics, etc.

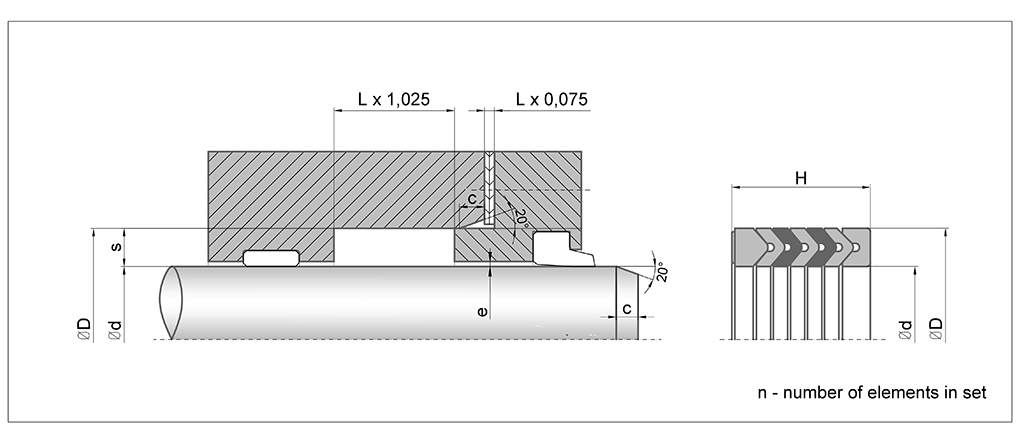

Gland length, L

Adjustable housings have the advantage of allowing adjustments of the axial force applied to the seal set. After a long period of operation and the occurrence of seal wear, this type of housing allows tightening of the seal and prolonging its service life.

For adjustable housings, it is recommended to extend the installation site by 2.5% and the possibility of subsequent adjustment of 7.5% from the “L” dimension, by installing a washer.

| MATERIAL | ||

|---|---|---|

| Material Set Code | SN107 | SF105 |

| Rubber | NBR | FPM |

| Fabric | Cotton | Cotton |

Alternate materials:

For very low temperature applications up to -60 C, or excellent oils-rubber compatybility in special applications a few materials are recommended and available on request.

| Pressure, Speed | |

|---|---|

| Working pressure, p | 40 Mpa |

| Running speed v | 0,5 m/s |

| Medium, Working Temperature | ||

|---|---|---|

| Material Set Code | SN107 | SF105 |

| Hydraulic oils: HL, HLP | ‘-30.. +100 ˚C | ‘-15.. +150 ˚C |

| HFA, HFB fluids | ‘+5..+60 °C | ‘+5..+60 °C |

| HFC fluids | ‘-30..+60 °C | ‘-15.. +60 ˚C |

| HFD fluids | – | ‘-15.. +150 ˚C |

| Water | ‘+5..+100 °C | ‘+5..+ 80 ˚C |

| Mineral greases | ‘-30..+100°C | ‘-15.. +150 ˚C |

| Tolerances | ||

|---|---|---|

| Ød | Clearance fit, emax | ØD |

| … 80 | H9/f8 | H11 |

| > 80 … 120 | H8/f8 | H11 |

| > 120 … 500 | H8/f7 | H11 |

| > 500 … 630 | H8/f7 | H10 |

| > 630 … 800 | H8/f7 | H10 |

| Surface quality* | ||

|---|---|---|

| Surface roughness | Ra | Rmax |

| Sliding surfaces, a | 0,05 to 0,3μm | ≤ 2,5 μm |

| Groove base, b | ≤ 1,6 μm | ≤ 6,3 μm |

| Groove flanks, d | ≤ 3,0 μm | ≤ 15 μm |

| Chamfer, f | ≤ 4,0 μm | ≤ 16 μm |

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

| Profile width (S) | Installation slope (C) |

|---|---|

| 5 | 3 |

| 6 | 3 |

| 7.5 | 5 |

| 10 | 5 |

| 12.5 | 7.5 |

| 15 | 7.5 |

| 20 | 10 |

Ød | ØD | L | S | n | Material | Order code | ||

|---|---|---|---|---|---|---|---|---|

20 |

30 |

18.50 |

5 |

7 |

SN107 |

R02-202001 |

||

22 |

32 |

18.50 |

5 |

7 |

SN107 |

R02-202002 |

||

25 |

37 |

22.5 |

6 |

7 |

SN107 |

R02-202003 |

||

28 |

40 |

22.5 |

6 |

7 |

SN107 |

R02-202004 |

||

30 |

42 |

22.5 |

6 |

7 |

SN107 |

R02-202005 |

||

32 |

44 |

22.5 |

6 |

7 |

SN107 |

R02-202006 |

||

35 |

47 |

22.5 |

6 |

7 |

SN107 |

R02-202007 |

||

36 |

48 |

22.5 |

6 |

7 |

SN107 |

R02-202008 |

||

40 |

52 |

22.5 |

6 |

7 |

SN107 |

R02-202009 |

||

42 |

54 |

22.5 |

6 |

7 |

SN107 |

R02-202010 |

||

45 |

60 |

22.5 |

7.5 |

7 |

SN107 |

R02-202011 |

||

50 |

65 |

22.5 |

7.5 |

7 |

SN107 |

R02-202012 |

||

55 |

70 |

22.5 |

7.5 |

7 |

SN107 |

R02-202013 |

||

56 |

71 |

22.5 |

7.5 |

7 |

SN107 |

R02-202014 |

||

60 |

75 |

22.5 |

7.5 |

7 |

SN107 |

R02-202015 |

||

63 |

78 |

22.5 |

7.5 |

7 |

SN107 |

R02-202016 |

||

65 |

80 |

22.5 |

7.5 |

7 |

SN107 |

R02-202017 |

||

70 |

85 |

22.5 |

7.5 |

7 |

SN107 |

R02-202018 |

||

75 |

90 |

22.5 |

7.5 |

7 |

SN107 |

R02-202019 |

||

80 |

95 |

22.5 |

7.5 |

7 |

SN107 |

R02-202020 |

||

85 |

100 |

22.5 |

7.5 |

7 |

SN107 |

R02-202021 |

||

20 |

30 |

18.50 |

5 |

7 |

SF105 |

R02-202022 |

||

22 |

32 |

18.50 |

5 |

7 |

SF105 |

R02-202023 |

||

25 |

37 |

22.5 |

6 |

7 |

SF105 |

R02-202024 |

||

28 |

40 |

22.5 |

6 |

7 |

SF105 |

R02-202025 |

||

30 |

40 |

22.5 |

6 |

7 |

SF105 |

R02-202026 |

||

32 |

44 |

22.5 |

6 |

7 |

SF105 |

R02-202027 |

||

35 |

47 |

22.5 |

6 |

7 |

SF105 |

R02-202028 |

||

36 |

48 |

22.5 |

6 |

7 |

SF105 |

R02-202029 |

||

40 |

52 |

22.5 |

6 |

7 |

SF105 |

R02-202030 |

||

42 |

54 |

22.5 |

6 |

7 |

SF105 |

R02-202031 |

||

45 |

60 |

22.5 |

7.5 |

7 |

SF105 |

R02-202032 |

||

50 |

65 |

22.5 |

7.5 |

7 |

SF105 |

R02-202033 |

||

55 |

70 |

22.5 |

7.5 |

7 |

SF105 |

R02-202034 |

||

56 |

71 |

22.5 |

7.5 |

7 |

SF105 |

R02-202035 |

||

60 |

75 |

22.5 |

7.5 |

7 |

SF105 |

R02-202036 |

||

63 |

78 |

22.5 |

7.5 |

7 |

SF105 |

R02-202037 |

||

65 |

80 |

22.5 |

7.5 |

7 |

SF105 |

R02-202038 |

||

70 |

85 |

22.5 |

7.5 |

7 |

SF105 |

R02-202039 |

||

75 |

90 |

22.5 |

7.5 |

7 |

SF105 |

R02-202040 |

||

80 |

95 |

22.5 |

7.5 |

7 |

SF105 |

R02-202041 |

||

85 |

100 |

22.5 |

7.5 |

7 |

SF105 |

R02-202042 |