Rod U-Ring R01

DESCRIPTION

U-Ring R01 is a U-seal with an asymmetric profile and shortened inner lip. The recommended working pressure is up to 10 MPa. If the protective ring is installed, the working pressure will increase to 16 MPa. It has very good static and dynamic tightness and it is a good choice for specific requirements, wide operating temperature range and easy installation.

APPLICATION

Light hydraulic cylinders.

Pneumatic cilinders

Earth moving equipment

Industrial vehicles

Agriculture equipment

| Standard material | ||||

|---|---|---|---|---|

| Material base | NBR 85 | NBR 85 | NBR 80 | FPM 85 |

| Material code | N4280 | N5185 | N7272 | F9193 |

Alternate materials:

For applications that may require alternative materials or for verification current availability of tools and part numbers, contact us.

| Pressure, Speed | |

|---|---|

| Working pressure, P | 10 MPa |

| Running speed, v | 0,5 m/s |

| Medium, Working Temperature | ||||

|---|---|---|---|---|

| Material code | N4280 | N5185 | N7272 | F9193 |

| Hydraulic oils HL, HLP | -30 to 100˚C | -50 to 90˚C | -60 to 80˚C | -15 to +200˚C |

| HFA, HFB fluids | +5 to +60˚C | +5 to +60˚C | +5 to +60˚C | – |

| HFC fluids | -30 to +60˚C | -30 to +60˚C | -30 to +60˚C | – |

| HFD fluids | – | – | – | -15 to +200˚C |

| Water | +5 to +90˚C | +5 to +90˚C | +5 to +80˚C | – |

| Mineral greases | -30 to +100˚C | -50 to +90˚C | -60 to +80˚C | -15 to +200˚C |

| Max. permissible gap dimension, emax | ||

|---|---|---|

| Max operating pressure |

S ≤ 7,5mm | S > 7,5mm |

| 5 Mpa | 0,30 | 0,35 |

| 10 Mpa | 0,20 | 0,25 |

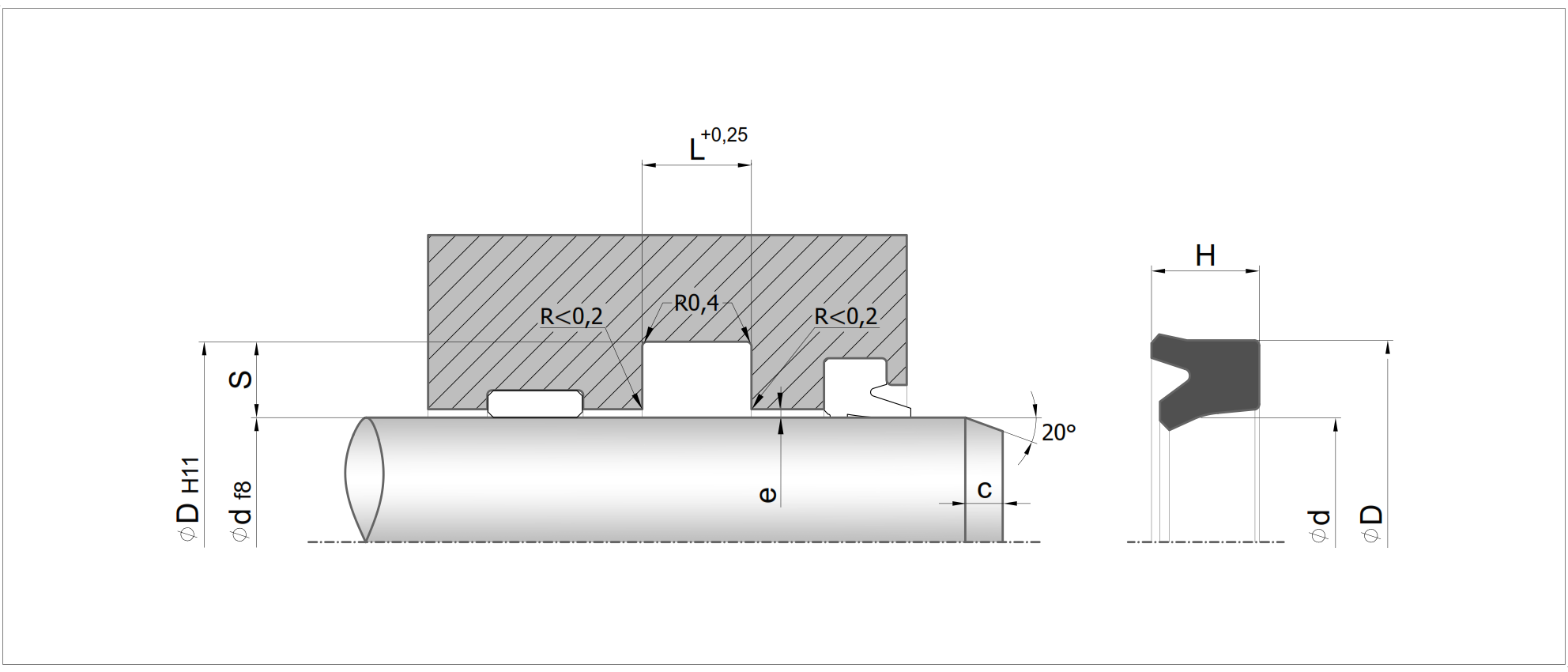

| Surface quality* | ||

|---|---|---|

| Surface roughness | Ra | Rmax |

| Sliding surfaces | 0.05 .. 0,3μm | ≤ 2,5 μm |

| Groove base | ≤ 1,6 μm | ≤ 6,3 μm |

| Groove flanks | ≤ 3,0 μm | ≤ 15 μm |

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

ØD | Ød | H | L | S | C | Material | Order code | ||

|---|---|---|---|---|---|---|---|---|---|

36 |

51 |

10 |

11 |

7.5 |

5.5 |

N7272 |

R01-201184 |

||

40 |

50 |

7 |

7.5 |

5 |

4.5 |

N7272 |

R01-201185 |

||

40 |

55 |

10 |

11 |

7.5 |

5.5 |

N7272 |

R01-201186 |

||

45 |

55 |

7 |

7.5 |

5 |

4.5 |

N7272 |

R01-201187 |

||

45 |

60 |

10 |

11 |

7.5 |

5.5 |

N7272 |

R01-201188 |

||

50 |

60 |

7 |

7.5 |

5 |

4.5 |

N7272 |

R01-201189 |

||

50 |

65 |

10 |

11 |

7.5 |

5.5 |

N7272 |

R01-201190 |

||

55 |

75 |

12 |

13 |

10 |

6 |

N7272 |

R01-201191 |

||

56 |

76 |

12 |

13 |

10 |

6 |

N7272 |

R01-201192 |

||

60 |

72 |

8.5 |

9.5 |

6 |

5 |

N7272 |

R01-201193 |

||

60 |

80 |

12 |

13 |

10 |

6 |

N7272 |

R01-201194 |

||

63 |

75 |

8.5 |

9.5 |

6 |

5 |

N7272 |

R01-201195 |

||

63 |

83 |

12 |

13 |

10 |

6 |

N7272 |

R01-201196 |

||

65 |

85 |

12 |

13 |

10 |

6 |

N7272 |

R01-201197 |

||

70 |

82 |

8.5 |

9.5 |

6 |

5 |

N7272 |

R01-201198 |

||

70 |

90 |

12 |

13 |

10 |

6 |

N7272 |

R01-201199 |

||

75 |

95 |

12 |

13 |

10 |

6 |

N7272 |

R01-201200 |

||

80 |

92 |

8.5 |

9.5 |

6 |

5 |

N7272 |

R01-201201 |

||

80 |

100 |

12 |

13 |

10 |

6 |

N7272 |

R01-201202 |

||

85 |

105 |

12 |

13 |

10 |

6 |

N7272 |

R01-201203 |

||

90 |

102 |

8.5 |

9.5 |

6 |

5 |

N7272 |

R01-201204 |

||

90 |

110 |

12 |

13 |

10 |

6 |

N7272 |

R01-201205 |

||

100 |

115 |

10 |

11 |

7.5 |

5.5 |

N7272 |

R01-201206 |

||

100 |

125 |

15 |

16 |

12.5 |

6.5 |

N7272 |

R01-201207 |

||

110 |

130 |

14 |

15 |

10 |

6 |

N7272 |

R01-201208 |

||

110 |

135 |

18 |

19 |

12.5 |

6.5 |

N7272 |

R01-201209 |

||

120 |

145 |

18 |

19 |

12.5 |

6.5 |

N7272 |

R01-201210 |

||

125 |

145 |

14 |

15 |

10 |

6 |

N7272 |

R01-201211 |

||

125 |

155 |

18 |

19 |

15 |

7 |

N7272 |

R01-201212 |

||

140 |

160 |

14 |

15 |

10 |

6 |

N7272 |

R01-201213 |

||

140 |

170 |

18 |

19 |

15 |

7 |

N7272 |

R01-201214 |

||

150 |

180 |

18 |

19 |

15 |

7 |

N7272 |

R01-201215 |

||

160 |

190 |

22 |

23 |

15 |

7 |

N7272 |

R01-201216 |

||

10 |

20 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201052 |

||

12 |

22 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201053 |

||

14 |

24 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201054 |

||

16 |

26 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201055 |

||

18 |

28 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201056 |

||

20 |

30 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201057 |

||

22 |

32 |

7.3 |

8 |

5 |

4.5 |

F9193 |

R01-201058 |

||

25 |

35 |

7 |

7.5 |

5 |

4.5 |

F9193 |

R01-201059 |

||

25 |

40 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201060 |

||

30 |

45 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201061 |

||

35 |

50 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201062 |

||

36 |

46 |

7 |

7.5 |

5 |

4.5 |

F9193 |

R01-201063 |

||

36 |

51 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201064 |

||

40 |

50 |

7 |

7.5 |

5 |

4.5 |

F9193 |

R01-201065 |

||

40 |

55 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201066 |

||

45 |

55 |

7 |

7.5 |

5 |

4.5 |

F9193 |

R01-201067 |

||

45 |

60 |

10 |

11 |

7.5 |

5.5 |

F9193 |

R01-201068 |