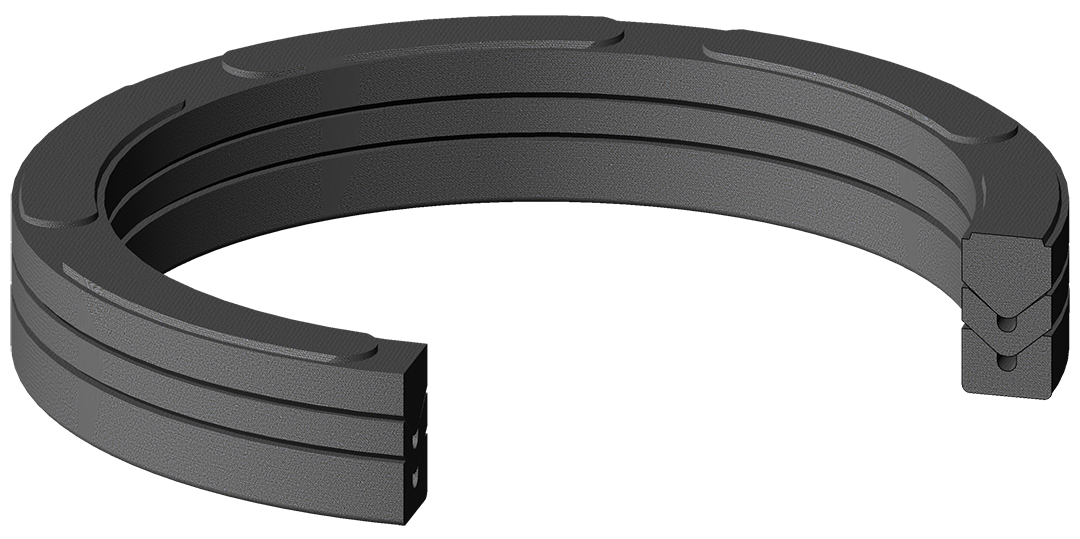

V-Seal Set P05

DESCRIPTION

Seal Set P05 is chevron set for sealing of hydraulic piston. Set includes usually three (n=3) pieces: Pressure ring (female adapter), one Roof-shaped seal (V-Ring) and support ring (male adapter).

Pressure ring (1) which can be subjected particulary heavy load are made of hard rubber reiforced fabrics with good resistance to wear and deformation.

Roof-shaped rings (2) are manufactured in cotton fabric impregnated with rubber and minimum one piece is included to set

Support ring (3) are made in hard rubber reinforced fabric or in hard and inert plastics (POM).

An additional V-rings ( n= 2; 3 ili više) should be used for large diameters or special operating conditions, e.g. horizontal position of large cylinders, piston deflection etc. In this cases height of Seal Set (H) and lenght of groove (L) need to be different. Please contact our Technical department

V-Seal Set P05 has excellent behavior in harsh conditions, exceptional wear resistance and long service life

APPLICATION

Mining equipment

Presses

Scrap cutters

Steel mill cylinders

Water hydraulics

Special cylinders

| Standard material | ||

|---|---|---|

| Material Set Code, standard | SN102 | SF106 |

| Rubber | NBR | FKM |

| Fabric reinforcement | Cotton | Cotton |

Alternate materials:

For very low temperature applications up to -60 C, or excellent oils-rubber compatybility in special applications a few materials are recommended and available on request.

| Pressure, Speed | |

|---|---|

| Working pressure, P | 40 MPa |

| Running speed, v | 0,5 m/s |

| Medium, Working Temperature | ||

|---|---|---|

| Material Set Code | SN102 | SF106 |

| Hydraulic oils: HL, HLP | -30.. +100 ˚C | -15.. +150 ˚C |

| HFA, HFB fluids | +5..+60 °C | +5..+60 °C |

| HFC fluids | -30..+60˚C | – |

| HFD fluids | – | -15.. +150 ˚C |

| Water | +5..+100 °C | +5..+ 80 ˚C |

| Mineral greases | -30..+100°C | -15.. +150 ˚C |

| Tolerances | ||

|---|---|---|

| Ød | Clearance fit, e | ØD |

| …80 | H9/f8 | h11 |

| > 80 … 120 | H8/f8 | h11 |

| > 120 … 500 | H8/f7 | h11 |

| > 500 … 630 | H8/f7 | h11 |

| > 630 … 800 | H8/f7 | h11 |

Read More

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

Surface quality*

Surface roughness

Ra

Rmax

Sliding surfaces, a

0,05 to 0,3μm

≤ 2,5 μm

Groove base, b

≤ 1,6 μm

≤ 6,3 μm

Groove flanks, e

≤ 3,0 μm

≤ 15 μm

Chamfer, f

≤ 4,0 μm

≤ 16 μm