Axial seal V-Ring MA

DESCRIPTION

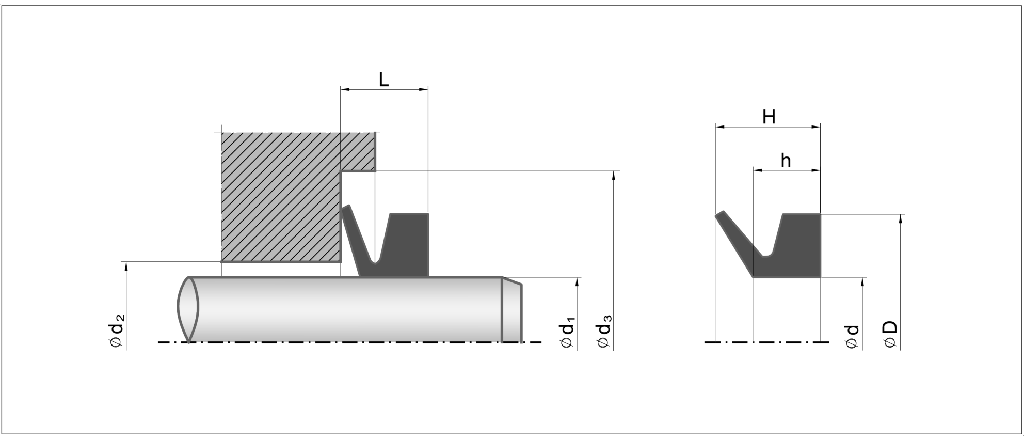

V-ring MA is deflector seal designed for axial acting and made from an elastomeric materials.

The V-Ring prevent the ingress of dirt, dust or water into bearing on rotary shafts at the same time retaining the grease. It can be used as secondary seal to protect primary seal in hostile environments. The V-Ring is mounted stretched directly on the shaft, where it is held in place by the inherent rubber forces. It rotates with the shaft and seals axially. It is in contact with an stationary counterface, perpendicular to the shaft.

The sealing lip is flexible and applies small contact pressure against the counterface allowing the seal to run dry in many applications

APPLICATION

To protect roller bearings and gears in wind turbines

Iron and steel industries

Minings

Pulp and papers industries

Transmissions

| Standard material | ||||

|---|---|---|---|---|

| Material base | NBR | HNBR | FKM | |

| Material code | N6783 | H3106 | F9172 | |

| Mineral oils | -40 … +100 oC | -30 … +130 oC | -10 … +180 oC | |

| Mineral grease | -40 … +100 oC | -30 … +130 oC | -10 … +180 oC | |

| Water | +5 … +100 oC | +5 … +100 oC | +5 … +80 oC | |

| Pressure, Speed | |||

|---|---|---|---|

| Pressure | 0,03 Mpa | 0,03 Mpa | 0,03Mpa |

| Sliding speed | 20 m/s | 20 m/s | 25 m/s |

| Axial support | ||

|---|---|---|

| At circumferential speeds of the V-Ring MA seal of approx. 6-8 m/s, it is necessary to maintain the correct distance of the sealing lip from the contact surface of the housing, and this is achieved through the axial support on the shaft. |

| Radial fixing | ||

|---|---|---|

| At higher circumferential speeds of approx. 10-12 m/s, the seal body is under the influence of centrifugal forces, so it tends to separate from the shaft. Then it is necessary to ensure the function of radial fixing of the seal body. Read More |

| Surface quality | ||

|---|---|---|

| Roughnees | Ra | Rmax |

| Sliding surfaces | ≤ 0.8 μm | ≤ 2.5 μm |

| Housing | ≤ 4.0 μm | ≤ 15.0 μm |

Nominal

size

| Ød | ØD | h

| H | Ød1

| Ød2 max

| Ød3 min

| L

| Material | Order code | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

500 |

450 |

480 |

14.3 |

25 |

480-530 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255028 |

||

550 |

495 |

525 |

14.3 |

25 |

530-580 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255029 |

||

600 |

540 |

570 |

14.3 |

25 |

580-630 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255030 |

||

650 |

600 |

630 |

14.3 |

25 |

630-665 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255031 |

||

700 |

630 |

660 |

14.3 |

25 |

665-705 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255032 |

||

725 |

670 |

700 |

14.3 |

25 |

705-745 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255033 |

||

750 |

705 |

745 |

14.3 |

25 |

745-785 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255034 |

||

800 |

745 |

775 |

14.3 |

25 |

785-830 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255035 |

||

850 |

785 |

815 |

14.3 |

25 |

830-875 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255036 |

||

900 |

825 |

855 |

14.3 |

25 |

875-920 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255037 |

||

950 |

865 |

895 |

14.3 |

25 |

920-965 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255038 |

||

1000 |

910 |

940 |

14.3 |

25 |

965-1015 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255039 |

||

1050 |

955 |

985 |

14.3 |

25 |

1015-1065 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255040 |

||

1100 |

1000 |

1030 |

14.3 |

25 |

1065-1115 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255041 |

||

1150 |

1045 |

1075 |

14.3 |

25 |

1115-1165 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255042 |

||

1200 |

1090 |

1120 |

14.3 |

25 |

1165-1215 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255043 |

||

1250 |

1135 |

1165 |

14.3 |

25 |

1215-1270 |

d1 +10 |

d1 +45 |

20 ±4.0 |

N6783 |

MA-255044 |