Piston Seal P36

DESCRIPTION

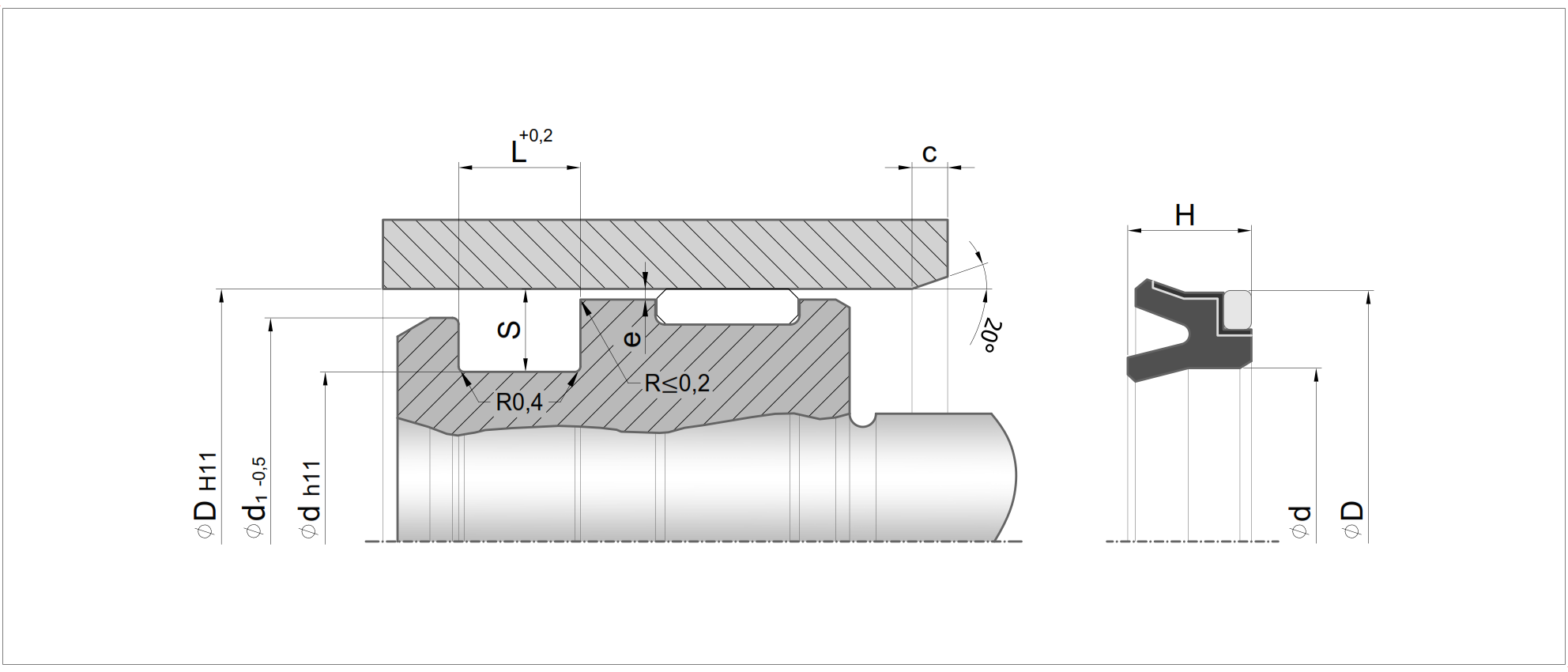

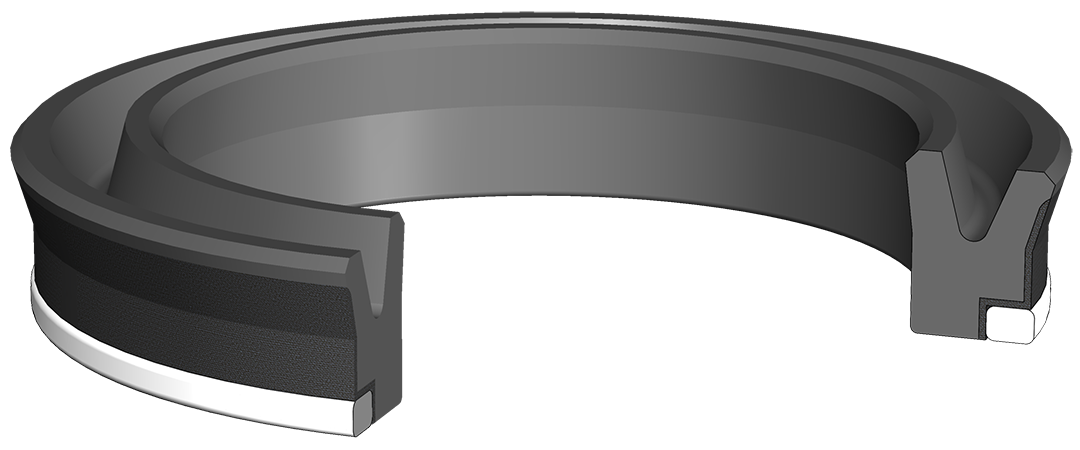

The single acting Piston seal P36 has an asymmetrical profile with a shortened outer lip and fabric reinforcement on the dynamic sealing side and an active back-up ring for gap closing.

The piston seal P36 can be installed in “back-to-back” position in a double-acting piston design with pressure on both sides.

Low friction due to fabric reinforcement, a wide operating temperature range, easy instalation in closed groove and FPM material in black or brown color are significiant advantages of this seal.

APPLICATION

Earth moving equipment

Special hydraulic cylinders.

Truck tail lift

Presses

Industrial wehicles

Mobile hydraulics

| Standard material | ||

|---|---|---|

| Material set code | SN218 | SF266 |

| Material base | NBR 80 Shore A | FPM 80 Shore A |

| Fabric | Cotton | Cotton |

| Back-up ring | Acetal resine (POM) | PTFE compound |

For very low temperature applications up to -60 C, or excellent medium-rubber compatybility in special applications a few materials are recommended and available on request

| Pressure, Speed | |

|---|---|

| Working pressure, P | 40 Mpa |

| Running speed, v | 0,5 m/s |

| Medium; Working Temperature | ||

|---|---|---|

| Material set code | SN218 | SF266 |

| Hydraulic oils HL, HLP | -30 to 100˚C | -15 to +150˚C |

| HFA, HFB fluids | +5 to +60˚C | – |

| HFC fluids | -30 to +60˚C | – |

| HFD fluids | – | -15 to +150˚C |

| Water | +5 to +90˚C | – |

| Mineral greases | -30 to +90˚C | -15 to +150˚C |

| Max. permissible gap dimension, emax | ||

|---|---|---|

| Max pressure | ØD ≤ 80 | ØD > 80 |

| 16 Mpa | 0,60 | 0,65 |

| 26 Mpa | 0,50 | 0,55 |

| 32 Mpa | 0,40 | 0,45 |

| 40 Mpa | 0,35 | 0,40 |

| Surface quality* | ||

|---|---|---|

| Surface roughness | Ra | Rmax |

| Sliding surfaces | 0.05.. 0,3 μm | ≤ 2,5 μm |

| Groove base | ≤ 1,6 μm | ≤ 6,3 μm |

| Groove flanks | ≤ 3,0 μm | ≤ 15 μm |

*Contact area Mr = 50% to 90% at cutting depth c=Rz/2 and reference line Cref=0%

ØD | Ød | H | L | S | Ød1 | C | Material | Order code | Sing in |

|---|---|---|---|---|---|---|---|---|---|

40 |

25 |

10 |

11 |

7.5 |

32.5 |

5 |

SN218 |

P36-211001 |

|

45 |

30 |

10 |

11 |

7.5 |

37.5 |

5 |

SN218 |

P36-211002 |

|

50 |

30 |

12 |

13 |

10 |

40 |

6 |

SN218 |

P36-211003 |

|

50 |

35 |

10 |

11 |

7.5 |

42.5 |

5 |

SN218 |

P36-211004 |

|

55 |

40 |

10 |

11 |

7.5 |

47.5 |

5 |

SN218 |

P36-211005 |

|

60 |

40 |

12 |

13 |

10 |

50 |

6 |

SN218 |

P36-211006 |

|

63 |

43 |

12 |

13 |

10 |

53 |

6 |

SN218 |

P36-211007 |

|

63 |

48 |

10 |

11 |

7.5 |

55.5 |

5 |

SN218 |

P36-211008 |

|

70 |

50 |

12 |

13 |

10 |

60 |

6 |

SN218 |

P36-211009 |

|

75 |

55 |

12 |

13 |

10 |

65 |

6 |

SN218 |

P36-211010 |

|

80 |

55 |

15 |

16 |

12.5 |

67.5 |

6.5 |

SN218 |

P36-211011 |

|

80 |

60 |

12 |

13 |

10 |

70 |

6 |

SN218 |

P36-211012 |

|

80 |

65 |

10 |

11 |

7.5 |

72.5 |

5 |

SN218 |

P36-211013 |

|

90 |

70 |

12 |

13 |

10 |

80 |

6 |

SN218 |

P36-211014 |

|

100 |

75 |

15 |

16 |

12.5 |

87.5 |

6.5 |

SN218 |

P36-211015 |

|

100 |

80 |

12 |

13 |

10 |

90 |

6 |

SN218 |

P36-211016 |

|

110 |

90 |

12 |

13 |

10 |

100 |

6 |

SN218 |

P36-211017 |

|

115 |

90 |

15 |

16 |

12.5 |

102.5 |

6.5 |

SN218 |

P36-211018 |

|

120 |

100 |

12 |

13 |

10 |

110 |

6 |

SN218 |

P36-211019 |

|

125 |

100 |

15 |

16 |

12.5 |

112.5 |

6.5 |

SN218 |

P36-211020 |

|

125 |

105 |

12 |

13 |

10 |

115 |

6 |

SN218 |

P36-211021 |

|

140 |

120 |

12 |

13 |

10 |

130 |

6 |

SN218 |

P36-211022 |

|

150 |

125 |

15 |

16 |

12.5 |

137.5 |

6.5 |

SN218 |

P36-211023 |

|

160 |

130 |

18 |

19 |

15 |

145 |

7.5 |

SN218 |

P36-211024 |

|

160 |

135 |

15 |

16 |

12.5 |

147.5 |

6.5 |

SN218 |

P36-211025 |

|

180 |

150 |

18 |

19 |

15 |

165 |

7.5 |

SN218 |

P36-211026 |

|

200 |

170 |

18 |

19 |

15 |

185 |

7.5 |

SN218 |

P36-211027 |

|

200 |

175 |

15 |

16 |

12.5 |

187.5 |

6.5 |

SN218 |

P36-211028 |

|

220 |

190 |

18 |

19 |

15 |

205 |

7.5 |

SN218 |

P36-211029 |

|

220 |

195 |

15 |

16 |

12.5 |

207.5 |

6.5 |

SN218 |

P36-211030 |

|

250 |

215 |

20 |

21 |

17.5 |

232.5 |

10 |

SN218 |

P36-211031 |

|

250 |

220 |

18 |

19 |

15 |

235 |

7.5 |

SN218 |

P36-211032 |

|

250 |

225 |

19 |

20.0 |

12.5 |

237.5 |

6.5 |

SN218 |

P36-211033 |

|

280 |

250 |

18 |

19 |

15 |

265 |

7.5 |

SN218 |

P36-211034 |

|

300 |

270 |

19 |

20.0 |

15 |

285 |

7.5 |

SN218 |

P36-211035 |

|

320 |

280 |

23 |

24 |

20 |

300 |

11 |

SN218 |

P36-211036 |

|

40 |

25 |

10 |

11 |

7.5 |

32.5 |

5 |

SF266 |

P36-211048 |

|

45 |

30 |

10 |

11 |

7.5 |

37.5 |

5 |

SF266 |

P36-211049 |

|

50 |

30 |

12 |

13 |

10 |

40 |

6 |

SF266 |

P36-211050 |

|

50 |

35 |

10 |

11 |

7.5 |

42.5 |

5 |

SF266 |

P36-211051 |

|

55 |

40 |

10 |

11 |

7.5 |

47.5 |

5 |

SF266 |

P36-211052 |

|

60 |

40 |

12 |

13 |

10 |

50 |

6 |

SF266 |

P36-211053 |

|

63 |

43 |

12 |

13 |

10 |

53 |

6 |

SF266 |

P36-211054 |

|

63 |

48 |

10 |

11 |

7.5 |

55.5 |

5 |

SF266 |

P36-211055 |

|

70 |

50 |

12 |

13 |

10 |

60 |

6 |

SF266 |

P36-211056 |

|

75 |

55 |

12 |

13 |

10 |

65 |

6 |

SF266 |

P36-211057 |

|

80 |

55 |

15 |

16 |

12.5 |

67.5 |

6.5 |

SF266 |

P36-211058 |

|

80 |

60 |

12 |

13 |

10 |

70 |

6 |

SF266 |

P36-211059 |

|

80 |

65 |

10 |

11 |

7.5 |

72.5 |

5 |

SF266 |

P36-211060 |

|

90 |

70 |

12 |

13 |

10 |

80 |

6 |

SF266 |

P36-211061 |